Huatai sunflower oil pressing machine adopts physical pressing technology, which is fully automatic from cleaning and impurity removal to pressing and extraction. It has high oil yield, pure oil, simple operation and labor saving. It is an ideal choice for small and medium and large-sized sunflower oil mills. The equipment is sturdy and durable, energy-saving and efficient, helping you easily produce high-quality sunflower oil.

Production Capacity: 10-1000TPD

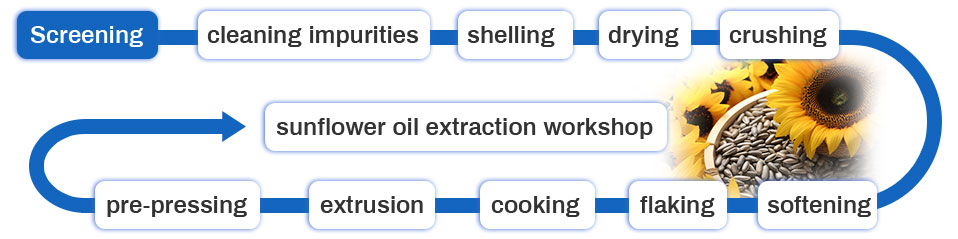

The Process of Sunflower Seed Oil Pretreatment and Pre-pressing Machine:

The Process of Sunflower Seed Oil Pretreatment and Pre-pressing Machine:

Screening → cleaning impurities → shelling →drying → crushing → softening→ flaking → cooking → extrusion → pre-pressing → sunflower oil extraction workshop

1. Cleaning

(1) During the harvesting, drying, transportation, and storage processes of oil crops, impurities such as sand, soil, stems, leaves, and iron will be mixed with them. If it is not removed before production, it will be very detrimental to sunflower oil production process. The impurities contained in oil can be divided into three categories: inorganic impurities, organic impurities and oily impurities.

① Inorganic impurities such as soil, sand, dust, and metals.

② Organic impurities such as stems and leaves, ropes, fruit shells and other seeds.

③ Immature grains containing oily impurities, foreign oils, damaged oils below the specified mesh size, diseases and insect pests, etc.

(2) Cleaning is a general term for the process of removing impurities contained in sunflower seeds. The cleaning technical requirements not only limit the impurity content in the oil, but also stipulate the oil content in the residue after cleaning.

① Screening: Screening is the method that uses the difference in particle size (width, thickness, length) of oilseed and impurities to separate impurities.

② Magnetic separation: Magnetic separation is the method that uses magnetism to remove magnetic metal impurities in oilseeds.

2. Separation of shell and kernel

① Shell content in kernels: Sunflower kernels should not exceed 10%.

② Shelled kernel rate (hand-picked): The shelled sunflower seeds should not exceed 1% (if there are intact seeds, the calculation will be after shelling).

3. Oilseed Drying

Oilseed drying refers to the process of dehydrating high-moisture oil to suitable moisture. Oilseeds are sometimes harvested during the rainy season and therefore have a high moisture content. Drying is very necessary for safe storage and for it to have the right moisture.

Heating oil with drying equipment can cause the water to evaporate. At the same time, the humidity in the air surrounding the oilseed must be lower than the surface humidity of the oilseed at that temperature. This creates a humidity difference, causing the water in the oilseed to continuously vaporize and escape.

The more air passes through the surface of the oilseed per unit time, the faster the oilseed will dehydrate. The drying equipment uses this principle to force hot air for drying.

4. Oilseed Crushing

The process of reducing oilseed particle size through mechanical means is called crushing. The purpose of crushing is to change the particle size of sunflower oilseeds to facilitate tableting; for pre-pressed cake, it is to make the size of the cake moderate and create good conditions for sunflower oil solvent extraction or secondary pressing.

5. Softening

Softening is to adjust the moisture and temperature of sunflower oilseed to make it soft. The process of increasing plasticity.

6. Oilseed Flaking

Flaking is the process of using machinery to compress sunflower oilseed from granules into flakes. The purpose of flaking is to destroy the cell tissue of oil and create favorable conditions for steaming and frying, so that the oilseed can be separated smoothly during pressing or extraction.

The basic requirements for flaking are that the raw materials should be thin, the surface should be uniform, less powder, no oil, soft when kneaded, loose when you let go, and the powderiness should be controlled within 1 mm from the sieve.

No more than 10% to 15% should be screened down, the thickness of the embryo body should be maintained at a certain level. After rolling the embryo, heat the embryo to control the soaking water to about 7% and the powderiness to less than 10%.

7. Cooking

Cooking refers to the process in which the raw embryo undergoes certain physical and chemical changes, changes its internal structure, and transforms into a mature embryo through processes such as moistening, heating, steaming, and frying.

8. Expansion

A new method based on extrusion is used to pretreat oil before extraction.

9. Prepressing

The power screw oil press is an oil press that uses power as the driving force and uses the spiral shaft to continuously rotate in the pressing cage to squeeze sunflower oilseed for oil extraction.

If sunflower oil pressing plant is used as a sunflower oil pre-pressing plant, consider setting up a buffer filter cake library between sunflower oil press plant and sunflower oil extraction plant to temporarily stack the pre-pressing filter cake when sunflower oil extraction plant breaks down.

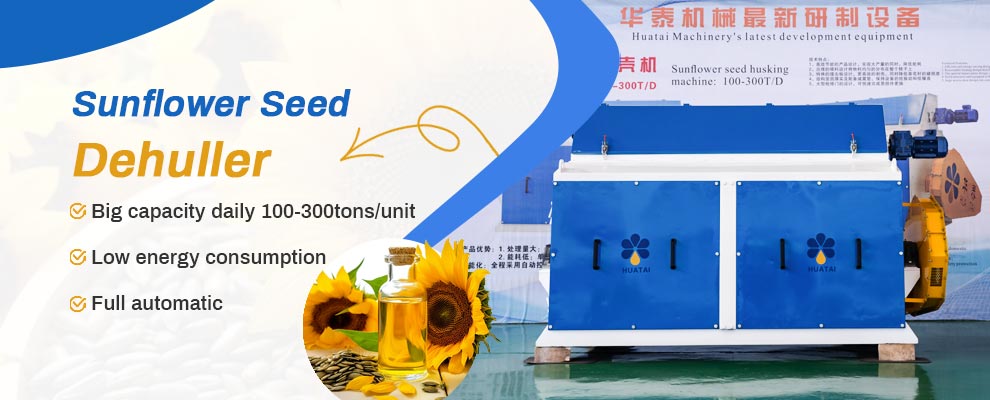

Technical features of Huatai sunflower oil press machine

Technical features of Huatai sunflower oil press machine

1) Energy-saving:frequency conversion technology is used to reduce energy consumption, and heat energy is recycled during the sunflower oil pressing process.

2) Oil quality: low-temperature pressing technology can retain more natural nutrients and meet the standards for healthy edible oils.

3) Full automation:PLC control system realizes automatic adjustment of parameters (pressure, temperature) to reduce manual intervention.

Application and advantages

Application and advantages

1) Applicable scenarios: small and medium-sized oil plants or large sunflower oil production lines (depending on the model), supporting continuous production.

2) Environmental design: some models are equipped with noise reduction and dust recovery devices to reduce environmental pollution.

Learn More about Huatai

Learn More about Huatai

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing machine, and is committed to providing customers with high-quality, cost-effective cooking oil equipment, mainly includes cooking oil press machine, edible oil extraction machine, vegetable oil refining equipment, complete edible oil production lines, etc. The equipment models are complete and the quality is good. Also, we provide customized services for edible oil mills to helps customers solve different product needs. Our edible oil processing machine are sold to more than a dozen countries and are well received by domestic and foreign customers.

All in all, to consult and purchase sunflower oil press machine, you can go to Huatai Oil Machinery. Please leave your inquiry information, such as: your raw material, machine capacity (TPD, how many tons to process per day), processing technology (Pressing, extraction, refining) or full set of production lines, etc. We will contact you ASAP and send you the complete fetures and specifications of the equipment. Welcome to visit our factory and for latest quotation.