| Capacity (T/D) | 8-10 |

| Residual Oil (%) | 6-8% |

| Power (KW) | 7.5 |

| External Dimension (MM) | 2270*970*1565 |

| Applicable Oilseeds | Multi Oilseeds: Peanut, Soybean, Sesame, Castor, Mustard, Copra, etc. |

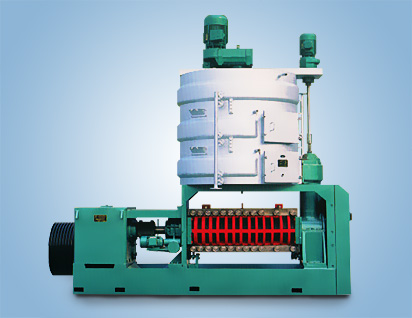

The screw oil press is one of the commonly used machines for squeezing cooking oil. It has a simple structure and is easy to operate. It can not only squeeze peanut oil, but also squeeze other oilseed, such as: soybean, corn, sunflower seed, cottonseed, coconut/copra, castor, mustard, safflower seed, etc. Then, Huatai Oil Machinery will introduce the screw oil press machine in detail from the aspects of structural features, working principle, machine advantages, etc.

The screw oil press is mainly composed of five parts: hopper, gearbox, pressing chamber, pressing screw and frame. Among them, the pressing screw is the key to the entire screw oil press machine. The choice of its material will affect the quality and service life of the cooking oil press machine. When you purchase a screw oil press, you can pay attention to it.

When the screw oil press is running, the processed oil seeds enter the pressing chamber from the hopper. The oil seeds are continuously pushed inward by the pressing screw for squeezing. Since the oil seeds are in motion in the pressing chamber of the oil press, under the condition of high pressure in the pressing chamber, a large friction resistance is generated between the oil seeds and the pressing screw, and between the oil seeds and the pressing chamber, so that friction can be generated between the oil seed particles, causing relative movement.

On the other hand, since the root diameter of the screw gradually increases and the pitch gradually decreases, when the screw rotates, the thread enables the oil seeds to move forward and flip outward, so that there is relative movement between the particles in the pressing chamber. The heat generated by friction also realizes the heat required for the cooking oil pressing process operation, which helps to promote the thermal denaturation of protein in oil seeds, destroy colloids, increase plasticity, and also reduce the viscosity of the oil, making it easier for the oil to precipitate, thereby accelerating the oil output rate of the oil press, squeezing out the oil in the oil seeds and flowing out from the gaps.

1) Reasonable pressing chamber and high oil yield: The screw oil press machine adopts directional pressure bearing, multi-stage advancement, one-time pressing, and greatly accelerated oil yield;

2) Closed protection, stable and convenient: The screw oil press has a delicate structure, occupies less space, and the transmission system adopts fully enclosed protection, which is stable and convenient to operate;

3) One machine for multiple uses: The screw oil press is widely used in the pressing of oil crops such as sunflower seed, peanuts, sesame, rapeseed, cottonseed, soybeans, tea seeds, and corn germ, coconut/copra, castor, etc.;

4) Novel conception, mechatronics: scientific design, reasonable structure, simple operation, stable and stable, using fully automated devices, it only takes a few minutes from feeding to finished products;

5) Excellent material and precise process: It is made of high-carbon steel, high-frequency quenching and heat-resistant treatment, with high hardness, high strength, good wear resistance, and adaptable to high temperature and high pressure continuous operation, which accelerates the service life of the oil press, and the service life can reach decades.

The above is the introduction of the screw oil press machine. Huatai Oil Machinery, as a manufacturer of cooking oil processing equipment, has many types of cooking oil press machine. In addition to screw oil presses, there are also automatic temperature-control oil presses, integrated oil presses, etc. We can also customize edible oil pressing production lines. We will recommend suitable cooking oil pressing equipment for you according to your specific needs. Welcome to consult!

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).