The 300-ton grain drying tower is a commonly used grain drying equipment. It evaporates the moisture in the grain through the contact between hot air and grain, thereby achieving the drying effect. Its working principle mainly includes three parts: the generation, transmission and drying process of hot air.

Production Capacity: 10-2000TPD

The core structure of Huatai's 300-ton grain drying tower consists of:

The core structure of Huatai's 300-ton grain drying tower consists of:

1. Hot air blower: As a heat source providing system, it generates high-temperature hot air

2. Hot air distribution system: Evenly distributes the hot air generated by the hot air blower into the drying tower to ensure that each grain can be fully dried.

3. Multi-layer drying tower: Composed of metal plates, the grain falls from top to bottom in the tower layer by layer, and is fully in contact with the hot air.

4. Dehumidification system: Including dehumidification fans and dehumidification pipes, responsible for discharging the evaporated moisture and humid hot air from the grain out of the tower.

5. Cleaning and dust removal device: Prevent impurities from entering the system, while recovering dust in the hot air to keep the environment clean.

6. Automatic control system: Integrates the monitoring and adjustment of parameters such as temperature, humidity, and air volume to achieve intelligent management of the drying process.

Working principle of grain drying tower:

Working principle of grain drying tower:

The working principle of grain drying tower is based on the principles of heat transfer and aerodynamics. The high-temperature hot air generated by the hot air system enters the tower through the hot air distribution system, forming a high-temperature and high-humidity environment. The wet grain enters from the top of the tower, and is fully in contact with the hot air during the falling process. The surface and internal moisture evaporate to form hot and humid air, which is then discharged out of the tower by the dehumidification system. During the drying process, the automatic control system adjusts the hot air temperature, air volume and the residence time of the grain in the tower according to the preset parameters to achieve the best drying effect.

Main uses of grain drying tower:

Main uses of grain drying tower:

1. Rapidly reduce the moisture content of grain to the safe storage standard and reduce the risk of mildew.

2. Improve the quality of grain and maintain the nutritional content and color of grain.

3. Suitable for grain processing needs of different scales, from small farms to large grain processing companies.

Performance characteristics of grain drying tower:

Performance characteristics of grain drying tower:

1. High efficiency and energy saving: using advanced heat recovery technology and optimized hot air circulation system to greatly reduce energy consumption and improve drying efficiency.

2. Uniform drying: The multi-layer tower design combined with the intelligent air volume distribution system ensures that each grain can be dried evenly to avoid local overheating or over-humidification.

3. Intelligent control: The integrated advanced automatic control system can monitor and adjust key parameters such as temperature, humidity, and air volume in real time to achieve precise control of the drying process. Environmental protection and low noise: The use of low-noise fans and environmentally friendly fuels reduces noise pollution and harmful gas emissions, and meets national environmental protection standards.

4. Strong adaptability: The drying process can be adjusted according to different grain types, moisture content and climatic conditions to meet the personalized needs of different users.

5. Environmental protection and low noise system.

Advantages of Huatai Grain Drying Tower:

Advantages of Huatai Grain Drying Tower:

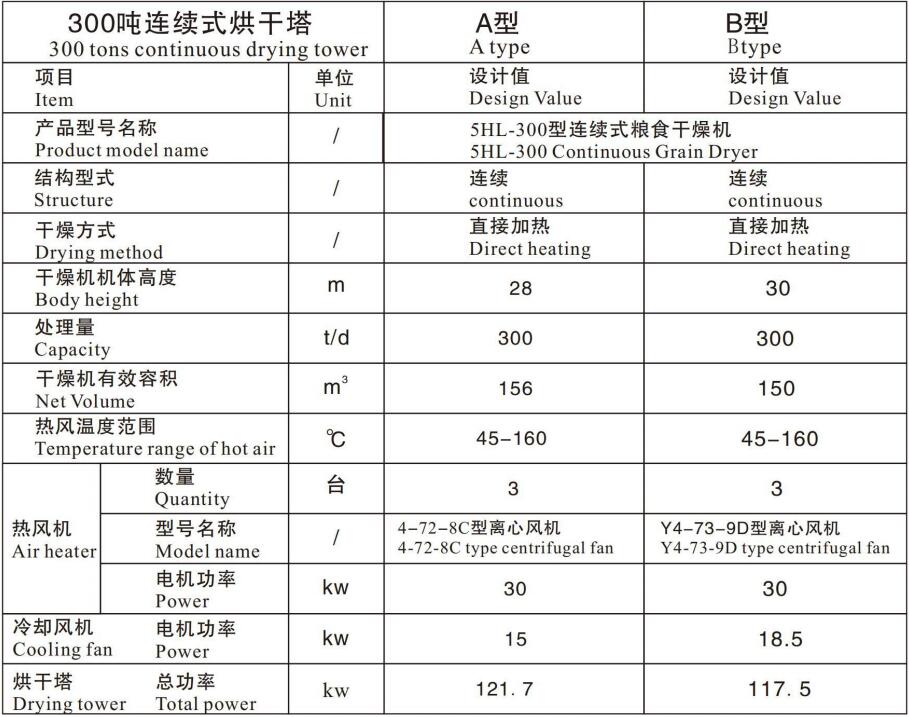

1. Daily processing 300 tons (24 hours) drying extent 13-15%.

2. Scientifically optimized layout, angular box arrangement, the use of counter-current drying technology to prevent frozen grain from being directly exposed to high temperature.The lower part adopts the reverse mixing section to reduce the moisture quickly. In each wind temperature section, tempering section is added to prevent the grain from fissure and cracking.In the middle drying section, a gelatinous box cross mechanism is set up for more uniform drying, and a cooling section is set up at the bottom, which reducesthe moisture content and the grain temperature at the same time, so as to store the grain after drying.Traditional drying tower, air inlet from the center (mixed flow), long process,high cost.Independent research and development of the new counter- current dryer, the abolition of the traditional intermediate air inlet, greatly improving the drying speed, in the drying cost of each catty grain cost savings of 0.5-1 cents.Our counter-current drying tower can also be used for sectional drying, which is very flexible and can dry as much or as little grain as you want.Traditional center- feed dryers, the tower must be filled before it can be turned on.

3. The whole tower is covered with reinforcement (2.3mm galvanized sheet stamped), the internal use of high- quality thick-walled seamless tubes and angle steel reinforcement, surrounded by side panels using large- scale equipment for overall processing and molding, the external insulation layer is made of 20mm high- density alumina silicate plate, and the thickness of color steel plate is 0.4mm.

4. Each fan adopts high-temperature resistant fan for boiler, whole bracket, steel plate molding,motor and fan adopts D-type or C-type transmission, long service life.

5. The hot air duct is insulated externally and the flange interface is sealed with high-temperature-resistant materials.

6. The barrel of the elevator is welded with galvanized plate, the head adopts DCYK hardened bevel gear reducer for mining, and it adopts high-strength and wear-resistant nylon dustpan and enhanced anti-tear lifting belt of famous domestic manufacturers.

7. The burner adopts imported components domestic assembly brand products, smooth combustion , small temperature fluctuation.

8. Control cabinet with dynamic light simulation drying process display,CPLC program control system, full automatic control of grain loading.

Strength of Huatai Oil Machinery

Strength of Huatai Oil Machinery

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing machine, and is committed to providing customers with high-quality, cost-effective cooking oil equipment, mainly includes cooking oil press machine, edible oil extraction machine, vegetable oil refining equipment, complete edible oil production lines, etc. The equipment models are complete and the quality is good. Also, we provide customized services for edible oil mills to helps customers solve different product needs. Our edible oil processing machine are sold to more than a dozen countries and are well received by domestic and foreign customers.

All in all, to consult and purchase grain drying machine, you can go to Huatai Oil Machinery. Please leave your inquiry information, such as: your raw material, machine capacity (TPD, how many tons to process per day), processing technology, or full set of production lines, etc. We will contact you ASAP and send you the complete fetures and specifications of the equipment. Welcome to visit our factory and for latest quotation.