Henan Huatai Oil Machinery is a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing capacity ranging from 10-5000 tons per day.

Engineering design of the complete peanut/groundnut oil making machine, including Factory site plan, mechanical engineering and electrical engineering;

Supplying complete mechanical & electrical equipment of peanut/groundnut oil making machine (FOB Main Port, China);

Supplying on-site guide for mechanical & electrical installation and commissioning of peanut/groundnut oil production line.

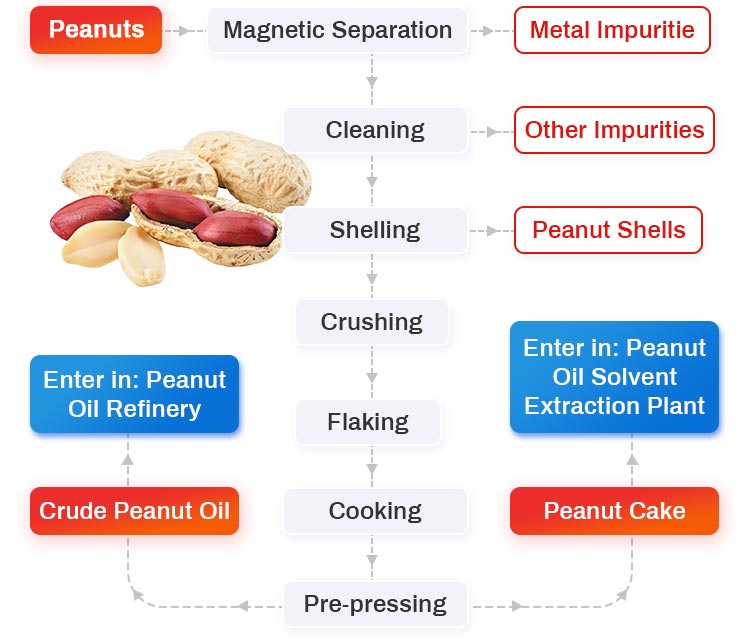

A complete groundnut oil processing plant includes the following processes: pretreatment, pre-pressing, extraction and refining.

1. Pretreatment Section of Peanut Oil Making Machine:

1. Pretreatment Section of Peanut Oil Making Machine:The groundnut oil pretreatment machine is to remove impurities in the raw materials and change the structural characteristics to make it meet the requirements of the peanut oil production process.

1) Magnetic separation: Remove metal impurities in peanuts to prevent damage to groundnut oil making machine and stability accidents.

2) Cleaning: Remove impurities in raw materials such as soil, stems and leaves, shells and moldy seeds.

3) Shelling: To speed up the oil yield and crude oil quality, and reduce wear on equipment.

4) Crushing: Crushing the peanut kernels into small pieces to speed up the pressing effect.

5) Flaking: Destroy oil cells, increase the surface area of oil seeds, and shorten the distance of oil output. In this way, it is conducive to extracting oil and speeding up the cooking effect.

6) Cooking: This treatment can speed up the pre-pressing oil yield and the quality of the cake, and adjust the moisture, temperature and plasticity of the embryo.

7) Pre-pressing: Squeeze out some of the oil in the raw materials and speed up the extraction effect.

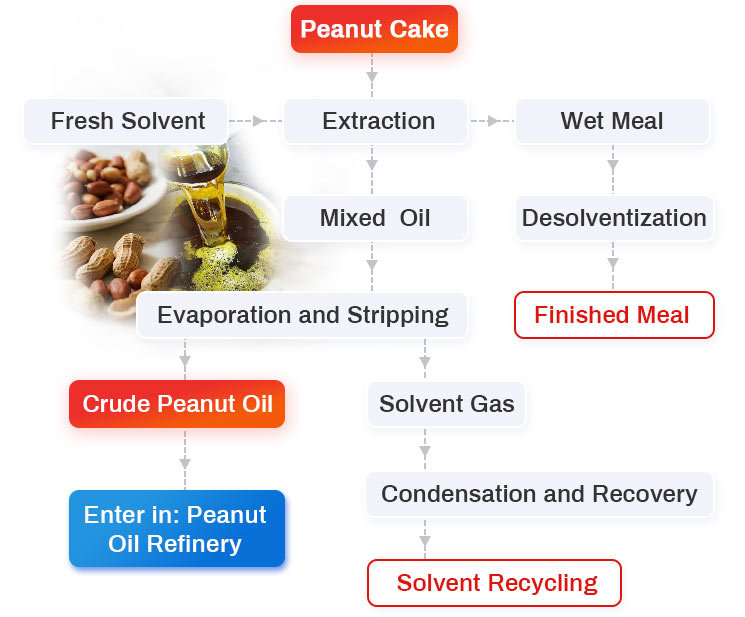

2. Extraction Section of Peanut Oil Production Machine:

2. Extraction Section of Peanut Oil Production Machine:The groundnut oil extraction machine extracts oil by suitable organic solvents. This method can get the most oil.

1) Extraction: Use solvent to extract the oil in the cake. The general solvent is No. 6 solvent or n-hexane;

2) Desolventization: Remove the solvent from the extracted cake and cool and recover it, and dry and cool the cake at the same time;

3) Evaporation and stripping: Use direct steam to heat the mixed oil, evaporate the solvent and concentrate the oil-water mixture;

4) Solvent recovery: Cool and recover the solvent, reduce solvent consumption, efficiently utilize raw materials, and speed up product quality.

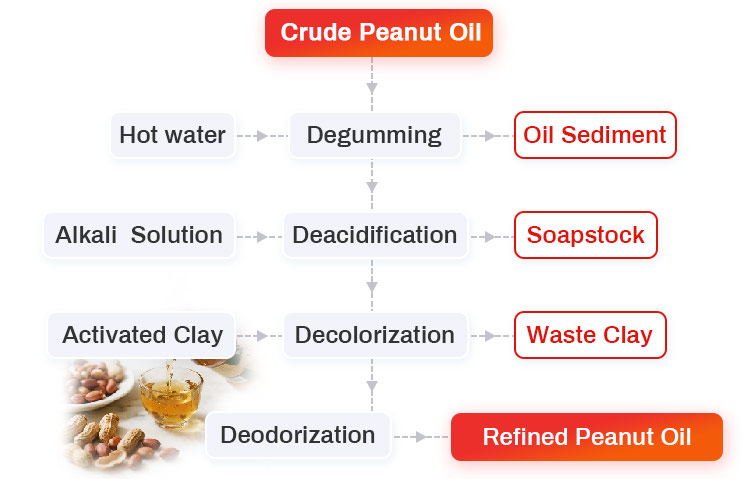

3. Refining Section of Peanut Oil Processing Machine:

3. Refining Section of Peanut Oil Processing Machine:Peanut oil Refinery is to purify crude oil and obtain high-quality peanut oil.

1) Degumming: To remove gum impurities and prepare for subsequent groundnut oil refining process.

2) Deacidification: To rremove free fatty acids in crude oil.

3) Decolorization: Add activated clay to remove pigments in crude oil, which can speed up the quality of oil.

4) Deodorization: To remove the odor and fishy smell in the oil and speed up the flavor of the oil.

Welcome to consult our groundnut oil production equipment.

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).