Henan Huatai Oil Machinery has more than 35 years of experience in sunflower oil making machine. Our company focuses on good sunflower oil production process with professional design, manufacturing, installation, commissioning, technical training team to ensure the quality of the sunflower oil production machine, and a complete after-sales system to provide customers with considerate services. We provide turnkey projects with a capacity of 10-5000 tons per day.

At the same time, we continue to innovate in science and technology, improve traditional processes, and combine modern technology with traditional processes, which not only reduces the consumption of various auxiliary materials, water and electricity, and saves costs, but also greatly improves the quality of sunflower oils, making them superior to the related peer sunflower oil making machine.

Sunflower oil has extremely rich nutritional value, containing more than 90% unsaturated fatty acids and 66% essential fatty acids for the human body. In order to speed up the oil yield of sunflower oil and obtain the best quality oil, sunflower oil making machine should include the following sections: pretreatment, pre-pressing, extraction, and refining.

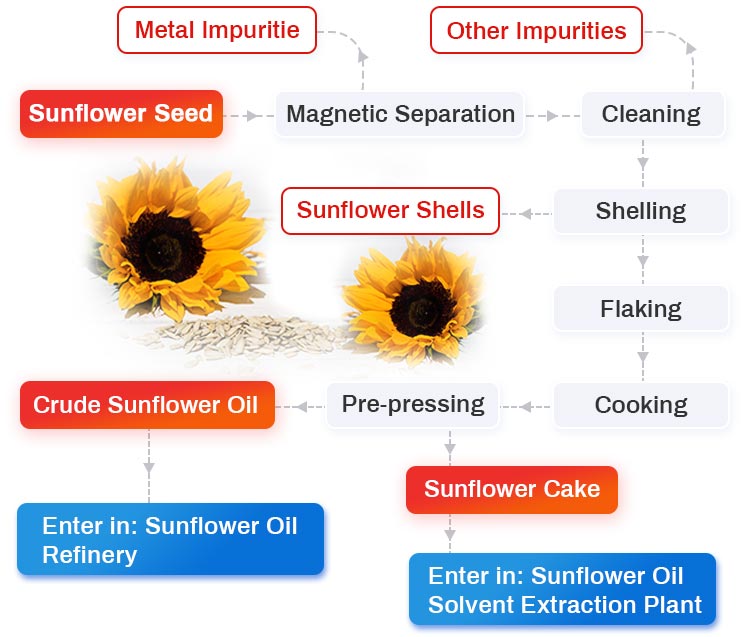

1. Sunflower Oil Pretreatment Section:

1. Sunflower Oil Pretreatment Section:The sunflower oil pretreatment machine is to remove impurities in the raw materials and change its shape to meet the requirements of oil production.

1) Magnetic separation: In order to remove metal impurities, so as to reduce wear and stability risks to the equipment.

2) Cleaning: To remove soil, straw, leaves, etc. from the raw materials.

3) Shelling: To speed up the oil yield and the quality of oil and cakes, reduce wear on equipment, etc., the shell needs to be removed.

4) Flaking: To destroy oilseed cells and speed up the contact area between equipment and oilseeds, it is conducive to oil extraction and cooking.

5) Cooking: This section can speed up the pre-pressing oil yield, speed up the quality of cakes, and adjust the moisture and temperature of embryos.

6) Pre-pressing: To squeeze out part of the oil in the raw materials to speed up the oil extraction effect.

2. Sunflower Oil Extraction Section:

2. Sunflower Oil Extraction Section:The sunflower oil extraction machine extracts oil through solvents, which can maximize the oil extraction effect.

1) Extraction: Extract the oil in the cake with solvent, the solvent is usually No. 6 n-hexane;

2) Desolventize: In order to remove and recycle the solvent in the cake, dry and cool the cake at the same time;

3) Evaporation and stripping: Direct steam heating of the mixed oil can extract the solvent. to purify the mixed oil;

4) Recycling of solvent: This is mainly to recycle the solvent, reduce solvent consumption, speed up production stability, and speed up product quality.

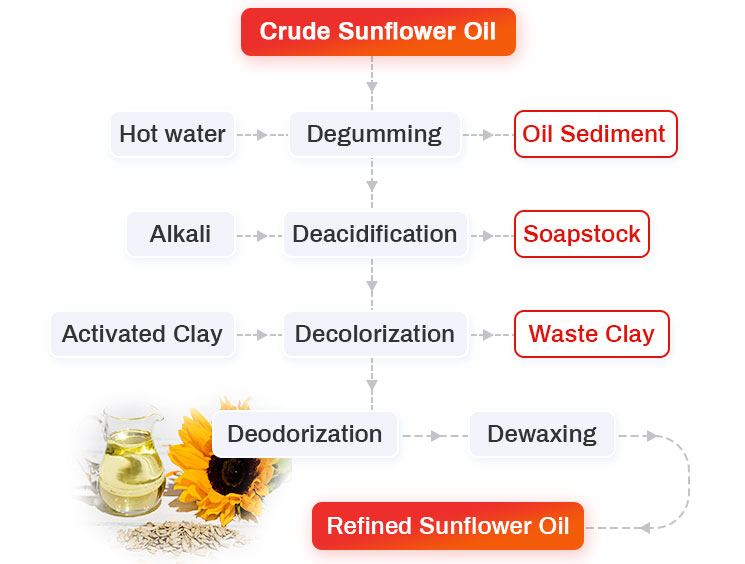

3. Sunflower Oil Refining Section:

3. Sunflower Oil Refining Section:The sunflower oil refining machine is to remove impurities in the crude oil and improve the oil quality.

1. Degumming: To remove colloid impurities to prepare for the subsequent sunflower oil refining process;

2. Deacidification: To remove free fatty acids in crude oil;

3. Decolorization: Add activated clay to absorb pigments in crude oil and improve the quality of oil;

4. Deodorization: To remove odor in oil and improve the taste, flavor, stability and oil quality;

5. Dewaxing: To remove wax in sunflower oil and speed up the oil quality.

Welcome to consult our sunflower oil production machine.

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).