The process flow of corn germ oil pretreatment machine: Cleaning → drying → softening → flaking → cooking → oil press → corn germ oil extraction plant

The Processing of Corn Germ Oil Pretreatment Machine:

1. Cleaning

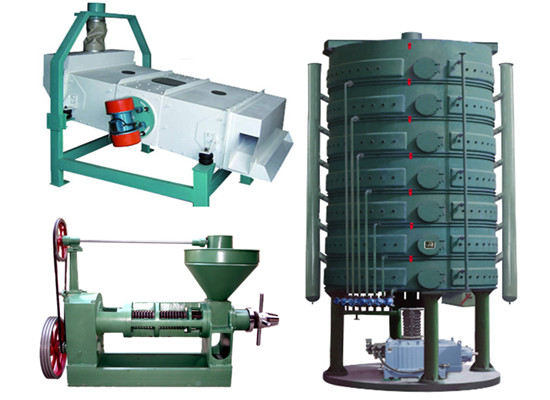

The corn germ recovered from making corn grits is mixed with a lot of corn flour, crushed powder and skin scraps, and needs to be sieved with a double-layer vibrating screen. The first layer of the screen mesh is used to remove impurities; the second layer is used to remove corn flour, grits and skin scraps to reduce the loss of corn germ.

2. Drying

In order to maintain the freshness of corn germ during storage and transportation, the cleaned corn germ needs to be sun-dried or oven-dried to a moisture content of less than 10%.

3. Softening

Softening is the first step in making oil from corn germ. In this process, the moisture content of the corn germ is reduced to less than 10% while undergoing heat treatment, so that the embryo undergoes plastic changes. Hot air dryers or hot steam roller dryers are commonly used for softening.

The temperature of the embryo should not rise too quickly when softening to prevent premature protein denaturation and loss of elasticity of the embryo, which will affect flaking, cooking, and oil pressing.

4. Flaking

After the corn germ is softened, it is then rolled into 0.3-0.4mm thin slices by a roller flaking machine, which promotes the destruction of the cell structure and shortens the oil path, which facilitates cooking and oil pressing.

5. Cooking

The moisture content of the embryo when it enters the cooker is not less than 12%. After 40-50 minutes of heating, the temperature of the embryo will finally exceed 100°C, and the moisture content of the embryo will gradually decrease from 12% to 3%-4%, until the color of the flake gradually changes to brown-red, and the aroma can be smelled without being burnt.

6. Pressing

Screw oil press or puffing pressing method is used, and the puffed material obtained enters the press to obtain better quality crude oil and cake. The prepared corn germ oil, commonly known as "crude oil" without refining, has 0.3% moisture and volatile substances, 0.2% impurities, 6% acid value, and 6% sediment.

It has a light yellow color and a normal smell. It is heated at 280°C, precipitates are precipitated. "Crude oil" is not resistant to storage due to its high moisture and impurity content. It needs to be refined through hydration, alkali refining and deodorization to obtain high-quality refined corn germ oil. This is the whole corn germ oil production line.