Introduction to the working principle of palm fruit oil extraction production line;

(1) The pretreatment equipment sterilizes the oil palm fruit.

(2) The sterilized palm fruit bunches are separated by the thresher to obtain the pulp rich in oil, which is crushed and crushed to obtain crude palm oil, palm oil pressing equipment, cake and fiber, and palm kernel can be obtained after separation of cake and fiber.

(3) The palm kernel is processed to obtain crude palm kernel oil.

(4) After the crude palm oil and crude palm kernel oil are diluted with water, they are precipitated and filtered to obtain relatively pure crude palm oil, and then the treated oil is sent to the crude oil tank for storage.

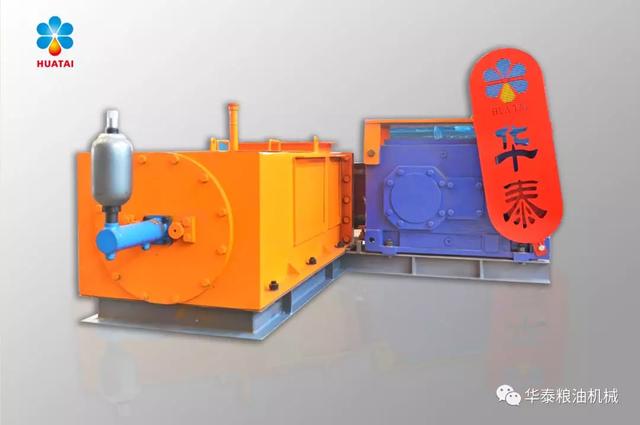

The main features of Huatai Oil Machinery's new palm oil processing technology:

1. Non-steam sterilization, low consumption, energy saving;

2. The new technology adopts dry sterilization, which greatly reduces the generation of wastewater, does not require sewage treatment machines, and has low costs;

3. Make full use of biomass fuels, palm oil equipment, such as empty fruit bunches, palm kernel shells, etc., and convert them into hot air and steam after burning to supply the entire workshop equipment;

4. The cake contains less water and can be directly used to process animal feed;

5. The palm crude oil after pressing has a more fragrant taste and good color.

6. Compared with traditional palm oil processing technology, the new technology equipment occupies a small area, refined palm oil equipment, especially sterilization and sewage treatment sections;

7. The system can generate electricity by itself, solving the problem of power shortage in many countries.

8. The new process is mainly suitable for small and medium-sized palm oil mills, with capacityof 5tph-10tph-20tph-30tph.

Website: https://www.oilpresscn.com/

Email: info06@cnoilmachine.com