Huatai Oil Machinery provides complete set of 20-5000TPD rapeseed oil production line.

1. Rapeseed Oil Production Line Usually Consists of The Following Oil Machines:

1. Rapeseed Oil Production Line Usually Consists of The Following Oil Machines:

Rapeseed oil pretreatment machine: Including rapeseed cleaning machines, crushers, dryers, etc., used to clean, crush and dry rapeseed to improve oil canola oil extraction efficiency.

Rapeseed oil pretreatment machine: Including rapeseed cleaning machines, crushers, dryers, etc., used to clean, crush and dry rapeseed to improve oil canola oil extraction efficiency.

Rapeseed oil press machine: Commonly screw oil press or hydraulic oil press are used to squeeze out oil from pretreated rapeseed.

Rapeseed oil press machine: Commonly screw oil press or hydraulic oil press are used to squeeze out oil from pretreated rapeseed.

Rapeseed oil filtration machine: Such as plate and frame filter or centrifugal filter, used to filter the crude rapeseed oil and remove impurities.

Rapeseed oil filtration machine: Such as plate and frame filter or centrifugal filter, used to filter the crude rapeseed oil and remove impurities.

Rapeseed oil refining machine: Including decolorization, deodorization, deacidification and other equipment, used to refine crude rapeseed oil and improve the quality of rapeseed oil.

Rapeseed oil refining machine: Including decolorization, deodorization, deacidification and other equipment, used to refine crude rapeseed oil and improve the quality of rapeseed oil.

Storage equipment: such as oil tanks, used to store refined rapeseed oil.

Storage equipment: such as oil tanks, used to store refined rapeseed oil.

Rapeseed oil filling equipment: Fill finished rapeseed oil into packaging containers of different specifications.

Rapeseed oil filling equipment: Fill finished rapeseed oil into packaging containers of different specifications.

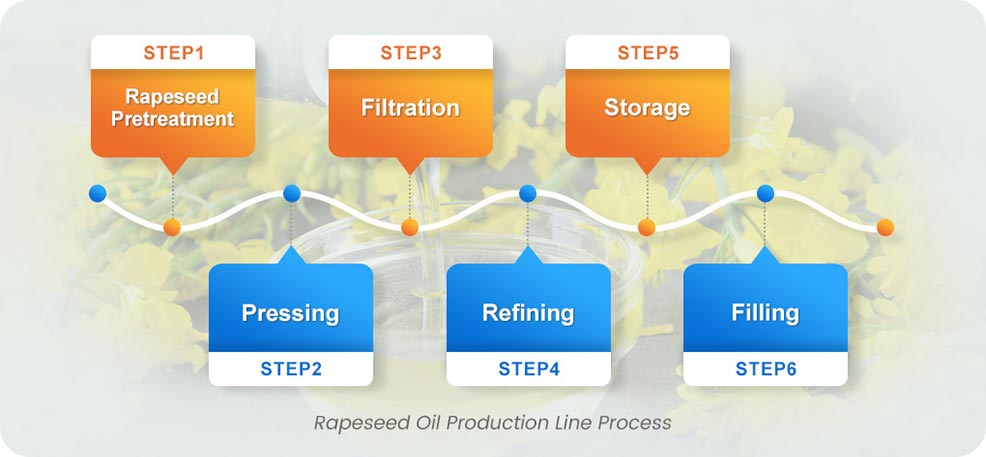

2. Process of Rapeseed Oil Production Line is Generally As Follows:

2. Process of Rapeseed Oil Production Line is Generally As Follows:

Rapeseed pretreatment: Clean, crush and dry the rapeseed to remove impurities and moisture.

Rapeseed pretreatment: Clean, crush and dry the rapeseed to remove impurities and moisture.

Pressing: Send the pretreated oilseed to rapeseed oil press for pressing to obtain crude oil.

Pressing: Send the pretreated oilseed to rapeseed oil press for pressing to obtain crude oil.

Filtration: Use filtration machine to remove impurities in crude oil.

Filtration: Use filtration machine to remove impurities in crude oil.

Refining: Improve the quality of oil through decolorization, deodorization, deacidification and other rapeseed oil refining processes.

Refining: Improve the quality of oil through decolorization, deodorization, deacidification and other rapeseed oil refining processes.

Storage: Store the refined rapeseed oil in oil tanks.

Storage: Store the refined rapeseed oil in oil tanks.

Filling: Fill rapeseed oil into packaging containers.

Filling: Fill rapeseed oil into packaging containers.

It should be noted that the specific equipment composition and process flow may be adjusted and optimized according to actual conditions. When designing and building a rapeseed oil production line, factors such as production scale, oil quality requirements, and cost-effectiveness need to be considered. Additionally, equipment selection and configuration should be determined based on specific needs and budget.