Henan Huatai Oil Machinery is a professional Corn Oil Production Machine Manufacturer in China.

Engineering design of the complete corn oil manufacturing machine, including factory site plan, mechanical engineering and electrical engineering;

Supplying complete mechanical & electrical equipment of corn oil production machine (FOB Main Port, China);

Supplying on-site guide for mechanical & electrical installation and commissioning of corn germ oil production line.

Corn germ oil has many benefits for the human body, is good for heart health, and is rich in vitamins and linoleic acid.

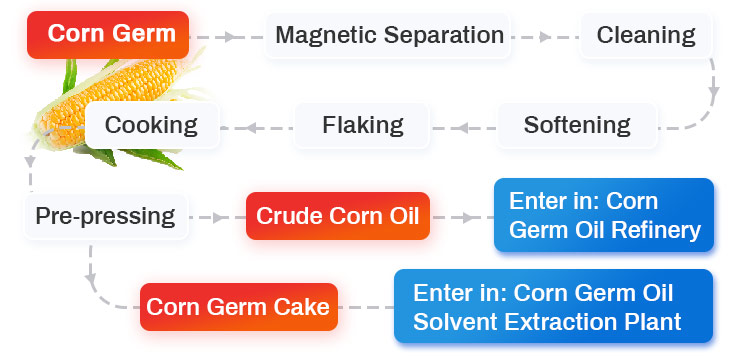

Here is the corn germ oil production process. The corn germ oil production line includes 3 sections: 1. Pretreatment section 2. Oil extraction section 3. Crude oil refining section.

1. Process Flow of the Pretreatment Section of Corn Germ Oil Production Line:

1. Process Flow of the Pretreatment Section of Corn Germ Oil Production Line:

The corn oil pretreatment section in the corn germ oil production line is more important, because it directly affects the oil pressing effect.

1. Create a good production environment.

2. Minimize oil loss, speed up oil yield, and speed up the quality of oil and meal.

3. Special use of separated impurities.

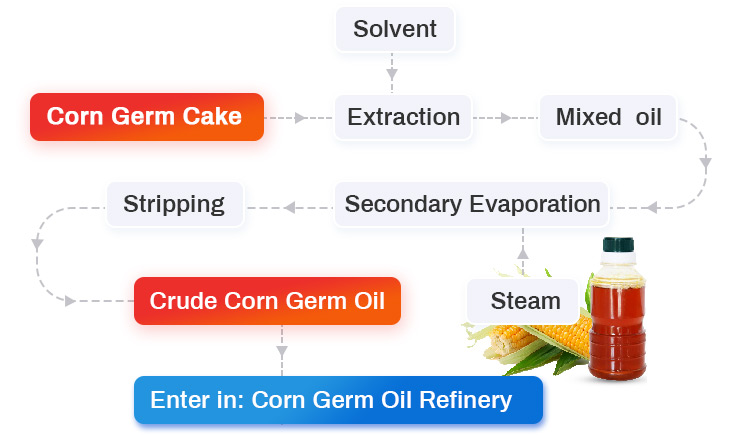

2. Process Flow of the Extraction Section in Corn Germ Oil Production Line:

2. Process Flow of the Extraction Section in Corn Germ Oil Production Line:

Extractor type: Rotary extractor, loop extractor, chain extractor

Corn germ oil extraction machine principle: Extract oil from corn germ by contacting to release with organic solvents for soaking or spraying.

1. High oil yield, less residual oil in meal.

2. Low labor.

3. Good working environment.

4. Good meal quality.

5. Negative pressure extraction speeds up crude oil quality.

1. Negative pressure evaporation can ensure better oil quality.

2. Extraction system can be applied to various oils.

3. The whole equipment is equipped with a waste gas recovery system

4. Save energy in total, maximize the recycling of heat energy and save steam

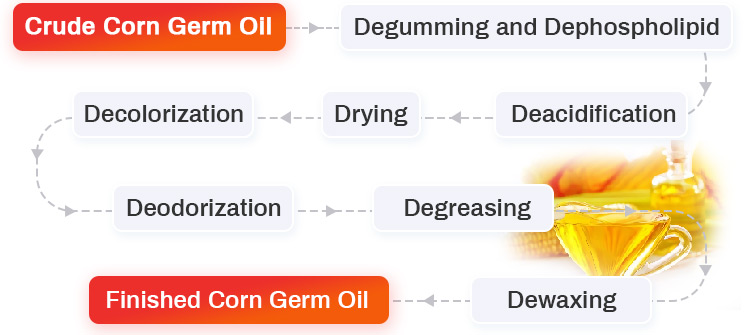

3. Process Flow of the Refining Section of Corn Germ Oil Production Line:

3. Process Flow of the Refining Section of Corn Germ Oil Production Line:

Corn germ oil refining machine principle: Refining is to remove harmful impurities and useless impurities according to different uses and needs, and obtain high-quality finished oil by comprehensive use of physical and chemical methods.

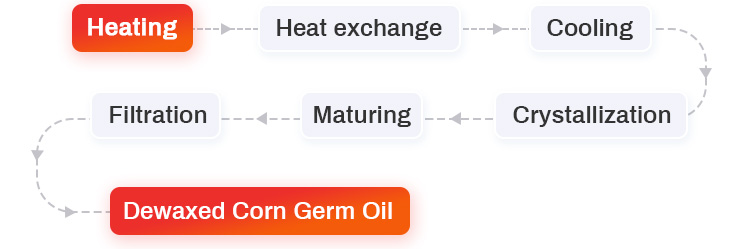

1) During dewaxing process, corn oil is first heat exchanged with dewaxed oil by the plate heat exchanger, and then cooled to a suitable temperature with frozen brine and put into the crystallization tank.

2) After the waxy oil is continuously cooled and crystallized to a suitable temperature, stirring is stopped and maintained for a long time to allow the uncrystallized wax to continue to crystallize and precipitate, and small crystals to continue to grow, that is, maturing.

3) The crystallized waxy oil is filtered by gravity to separate the oil and wax to obtain dewaxed corn oil.

1. The impurity content after refining needs to be less than 0.2%

2. The circulation system saves energy and money

3. Low oil consumption

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).