Henan Huatai Oil Machinery is a professional Cottonseed Oil Mill Project and Machine Manufacturer in China.

Engineering design of the complete cottonseed oil mill project, including Factory site plan, mechanical engineering and electrical engineering;

Supplying complete mechanical & electrical equipment of cottonseed oil mill plant (FOB Main Port, China);

Supplying on-site guide for mechanical & electrical installation and commissioning of cottonseed oil production line.

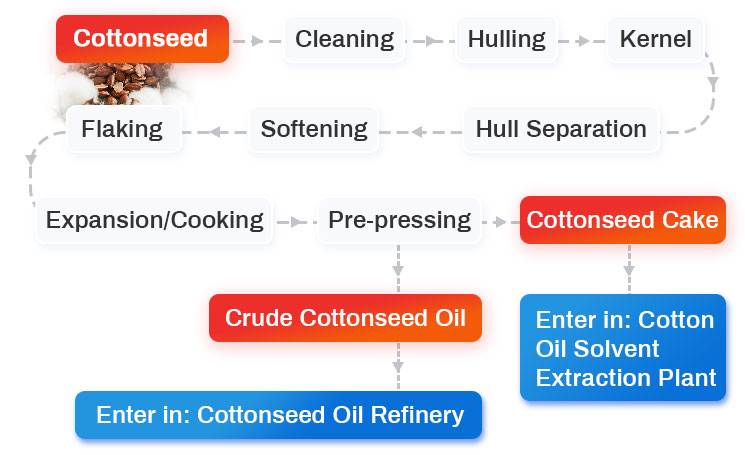

The oil content of cottonseed is about 14%-25%, which is relatively low. Therefore, in order to improve oil yield, it is recommended to use the pre-pressing -extraction method to produce cottonseed oil. The pre-pressing-extraction method to produce cottonseed oil requires cottonseed oil pretreatment machine, cottonseed oil pre-pressing equipment, cottonseed oil extraction machine and cottonseed oil refining machine. The following is a detailed introductio n to the specific cottonseed oil production process.

1. The Cottonseed Oil Pretreatment Section:

1. The Cottonseed Oil Pretreatment Section:

1. Cleaning: Cottonseed is subjected to air separation and magnetic separation to remove light impurities, heavy impurities and stone impurities in cottonseed. Excessive impurities will reduce the oil yield and affect the normal operation of the cottonseed oil equipment.

2. Shelling: Use a sheller to remove the outer shell of cottonseed to speed up the oil yield. During the shelling process, special attention should be paid to the uniform particle size of the cottonseed kernel after shelling to reduce the powder degree of shelling.

3. Kernel and shell separation: Use a kernel and shell separation screen to separate the cottonseed kernel and shell to obtain clean cottonseed kernel. The shell content in the kernel is required to be no more than 10%.

4. Softening: Softening pot can adjust the moisture content of cottonseed, increase its plasticity, facilitate subsequent processing, and reduce cottonseed oil machine wear and vibration.

5. Flaking: Flaking machine to press cottonseed kernels into thin slices, increase the surface area of the oil, destroy its cell structure, shorten the oil path, and speed up the oil yield. The thickness of the embryo after flaking is required to be no more than 0.5mm.

6. Cooking: Steaming and frying can adjust the temperature and moisture, which is conducive to the condensation of oil and accelerates the oil yield. The softening of cottonseed generally uses a three-layer or four-layer vertical cooking pan.

7. Pre-pressing: The pressing efficiency and stability of the cottonseed oil pressing machine are the key to the oil pressing process. The oil press produced by our company has the characteristics of large output, low cake residue and good cake quality.

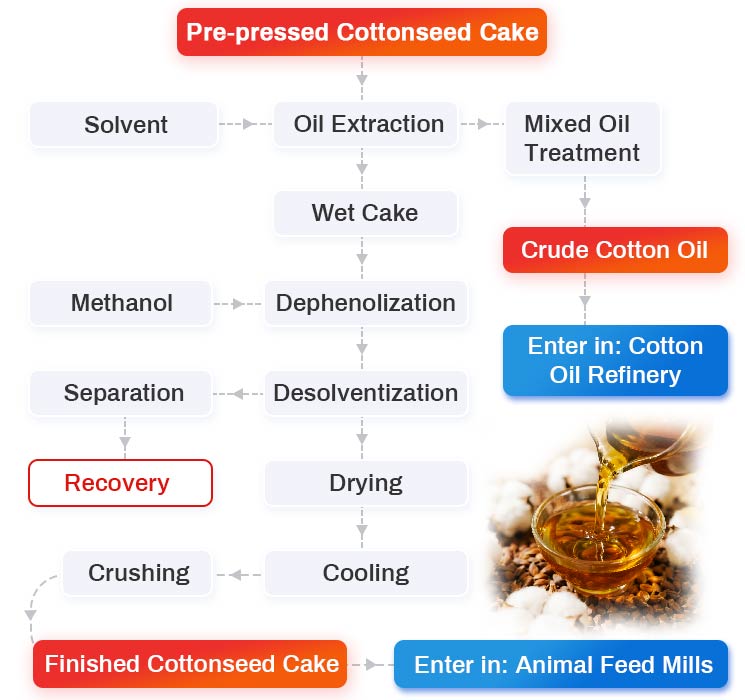

2. The Cottonseed Oil Extraction Process:

2. The Cottonseed Oil Extraction Process:

1) Liquid-liquid-solid extraction technology comprehensively considers the overall utilization of cottonseed resources. In the cottonseed oil pretreatment process, low-temperature treatment method is used to avoid the thermal denaturation of protein to the greatest extent, and ensure the nutritional value of cottonseed protein products.

2) 6# solvent oil and methanol as two solvents to extract cottonseed oil and remove cottonpol in steps to ensure the oil quality and the rapid and thorough dephenolization.

3) Special multi-stage dephenolization extraction equipment quickly extract a large amount of free gossypol in a short time, avoiding the formation of denatured gossypol, combined gossypol and other forms of gossypol derivatives. The free gossypol content in the product is less than 400mg/kg.

4) While dephenolization, the interaction between solvent and water removes toxic and harmful substances such as cottonseed sugar, tannin, phytic acid, aflatoxin and pesticide residues in cottonseed kernels, fully protecting the reasonable nutritional components in cottonseed protein.

5) This technology uses special dephenolization equipment and dryers, with high extraction efficiency and low equipment investment, solving the problems of solvent separation and recovery, and reducing solvent consumption to a minimum.

6) Low temperature process prevents pigments from being solidified into materials and oil products, and the pigment content in crude oil is low, so the quality of oil products is fully guaranteed.

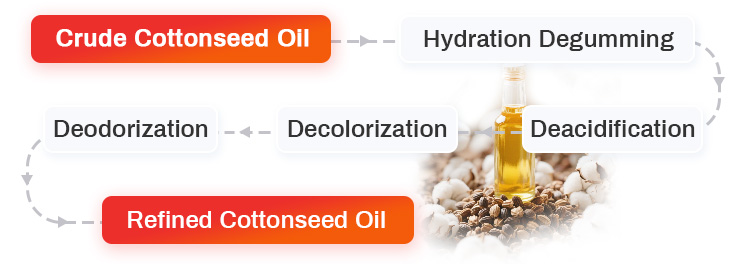

3. The Cottonseed Oil Refining Process:

3. The Cottonseed Oil Refining Process:Crude cottonseed oil needs to be refined and impurized by cottonseed oil refining machine to remove various impurities and trace elements such as colloid-soluble impurities, free fatty acids, pigments, moisture, wax, and cotton phenol in the crude oil to obtain the finished first-grade leached cottonseed oil.

Getting cottonseed oil by pretreatment-extraction process, the cottonseed oil machine investment is large, but the efficiency is high, the processing capacity is large, the production cost is low, the oil yield is high, and the degree of automation is high. It is very suitable for large oil plants with more than 30TPD processing capacity.

The selection of equipment manufacturers and equipment quality should be taken seriously, because the cooking oil extraction production line has high requirements for environmental safety, and the solvents used in oil extraction are flammable and explosive products. Therefore, the quality of the equipment and the manufacturer's production and installation experience are required to be high. When choosing an equipment manufacturer, it is necessary to consider many aspects before making a decision.

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).