Henan Huatai Oil Machinery is a professional Canola Oil Processing Plant and Equipment Manufacturer in China.

Engineering design of the complete canala oil processing plant, including Factory site plan, mechanical engineering and electrical engineering;

Supplying complete mechanical & electrical equipment of rapeseed oil processing plant (FOB Main Port, China);

Supplying on-site guide for mechanical & electrical installation and commissioning of rapeseed oil production line.

The common rapeseed oil processing methods are two: pressing and extraction. Rapeseed oil is a high-oil-content oil. Usually we use direct pressing to extract rapeseed oil, which is pure physical pressing and can retain the natural flavor of rapeseed oil. But, in order to ensure the rapeseed oil quality and maximize the benefits of the canola oil mill, large rapeseed oil processing plant will also adopt the process of pre-pressing and then extracting: First pre-pressing the rapeseed to get the oil, and then crushing the pre-pressed rapeseed cake and sending it to the rapeseed oil extraction machine to extract the remaining oil. This process is called the pre-pressing-extraction process. There are the two rapeseed oil processing process for you:

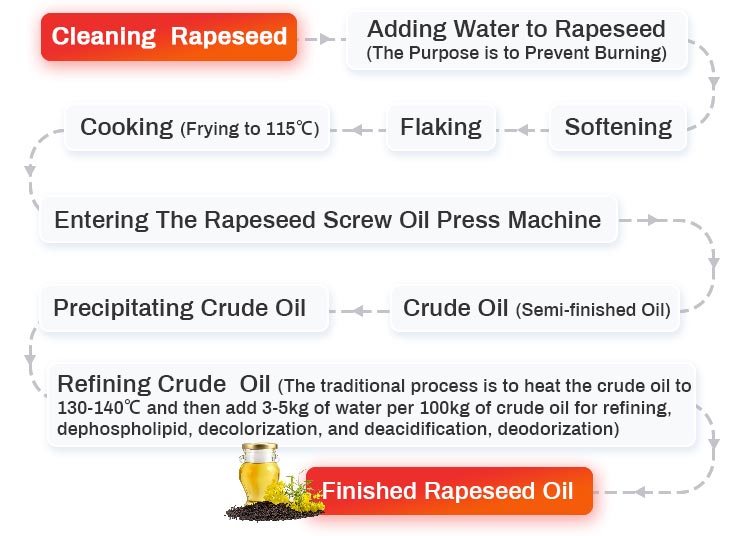

Rapeseed Oil Pressing Process:

Rapeseed Oil Pressing Process:

1) Cleaning of rapeseed before entering the rapeseed oil pressing machine. Through cleaning rapeseed, the loss of oilseed can be reduced, the oil yield can be accelerated, the quality of oilseed and cake can be accelerated, the processing capacity of canola oil pressing machine can be increased, the wear of rapeseed oil pressing equipment can be reduced, and the fly ash can be reduced, which is beneficial to environmental protection.

2) Soften the rapeseed. It is to crush large particles, or adjust the moisture and temperature of small particles of rapeseed to a suitable degree to make it quite plastic, so as to facilitate cooking. The general temperature is between 60 and 70℃. Flaking is conducive to the destruction of the cell structure of oilseeds, and it is easy to take out the oil in the cells. The thickness of rapeseed embryo is 0.2-0.3 microns.

3) Rapeseed oil pressing machine for pressing. The pretreated rapeseed is sent to the rapeseed oil pressing machine for pressing and oil extraction.

This stage is different from large-scale canola oil extraction method. It relies entirely on the pure physical pressing of canola oil pressing machine, does not contain other chemical solvents, and thus fully retains the nutritional components and original flavor of rapeseed.

Rapeseed Oil Extraction Process:

Rapeseed Oil Extraction Process:The rapeseed oil extraction plant has a large output, and the type, model and quantity of equipment need to be configured according to the scale of the canola oil plant, the grade of oil, the budget of the rapeseed oil plant, etc. Generally speaking, the equipment required by canola oil mill can be divided into the following four categories:

Rapeseed oil mills have a large output, and the cleaning and pretreatment of raw materials need to be operated by mechanized equipment. The equipment required generally includes cleaning screen, stone remover, flaking machine, cooking pot, etc.; the oilseed is processed through the above equipment to remove impurities such as stones and sand in the rapeseed, and then its original organizational structure is destroyed so that it can better extract oil.

The rapeseed oil extraction process is to adopt the mutual dissolution of oil and organic solvents. After pre-pressing the rapeseed into cake, the organic solvents such as n-hexane and the oil cake are contacted in the rapeseed oil extractor to extract and dissolve the oil, and then the solvent in the oil is removed by heating and steam stripping. The crude oil obtained is further refined and becomes the final edible oil.

In this way, the residual oil in the oil residue can be reduced to less than 1%. The advantages of the canola oil extraction process are that the meal cake contains less residual oil, high oil yield, low processing cost, high economic benefits, and high quality of the meal, which has a good feeding effect in the feed industry.

Rapeseed oil refining machine is an important equipment to ensure the quality of rapeseed oil, and it is also the last step in canola oil processing. The crude rapeseed oil is transported to the rapeseed oil refinery through a pipeline, after filtering through a plate and frame filter, and then the main processes such as degumming, deacidification, decolorization, deodorization, and dewaxing of the canola oil refining machine are to obtain the finished rapeseed oil.

The rapeseed oil after the above rapeseed oil refining process can meet the national standard of first-grade rapeseed oil, and the quality, storage time, and food safety are greatly improved.

* Please note: We don't recruit any workers and no Job chance.

In addition, please confirm that the following information is filled in:

1. Oil seed type, such as palm fruit, palm kernel, peanut, soybean, sunflower seed or other oil seed;

2. Oil processing equipment capacity: how many tons per day (tpd).