Henan Huatai Oil Machinery is a professional Rice Bran Oil Processing Plant and Rice Bran Oil Manufacturing Machinery Manufacturer in China.

Engineering design of the complete rice bran oil processing plant, including Factory site plan, mechanical engineering and electrical engineering;

Supplying complete mechanical & electrical equipment of rice bran oil processing plant (FOB Main Port, China);

Supplying on-site guide for mechanical & electrical installation and commissioning of rice bran oil production line.

The oil extracted from rice bran is called rice bran oil, it also called rice oil. Rice bran is a by-product obtained during rice processing. Since the oil content of rice bran raw materials is relatively low and it is easy to become rancid, engineers generally recommend that rice bran oil be produced by pretreatment-extraction process in the more than 30TPD processing capacity.

The rice bran oil production process includes rice bran pretreatment section, rice bran oil extraction section, rice bran oil refining and dewaxing section. Huatai Oil Machienry will give you a detailed introduction to the rice bran oil manufacturing process.

1) The rice bran obtained during rice processing will contain a small amount of impurities, so the rice bran and broken rice should be separated by a rice bran and tips separation screen to obtain pure rice bran.

2) The rice bran enters the conditioning pot and a small amount of steam (about 2% of the raw material) is introduced for softening and condition.

3) Enter the rice bran extruder and use the pressure difference to make it a porous and soft structure, which is conducive to subsequent rice bran oil extraction process.

4) The expanded rice bran enters the flat drying equipment for drying and cooling. The pretreated rice bran can be directly sent to the rice bran oil extraction workshop for processing, or it can be stored first (it can be stored for about 1 week).

1) After the rice bran is pretreated, the expanded rice bran particles obtained enter the rice bran oil extractor. After spraying the solvent n-hexane, the oil in the rice bran will dissolve in the solvent to form a mixed oil.

The mixed oil is filtered through a screen, and the relatively clean mixed oil will enter the mixed oil evaporation system.

2) Taking advantage of the fact that oil is almost non-volatile, while the solvent has a low boiling point and is easy to volatilize, the solvent is vaporized and evaporated by two evaporations and one stripping method to obtain rice bran oil.

3) The wet meal separated by filtration in the rice bran oil extraction machine contains a small amount of solvent. Water vapor is introduced into it for desolventizing and removing the solvent. The principle is the same as that of the mixed oil evaporation system.

4) The evaporated solvent will be cooled and recovered through the condensation recovery system, and enter the solvent recovery tank, waiting for the next production use.

| Item | Quality index |

| Smell and taste | It has the inherent smell and taste of crude rice bran oil, without peculiar smell |

| Water and volatile matter (%) | ≤ 0.20 |

| Insoluble impurities (%) | ≤ 0.20 |

| Acid value (KOH) (mg/g) | ≤ 4.0 |

| Peroxide value/(mmol/kg) | ≤7.5 |

| Residual solvent/(mg/kg) | ≤100 |

Rice bran oil refining machine includes heat transfer oil circulation system, steam boiler, vacuum system, etc. Rice bran oil refinery is a complete set of equipment.

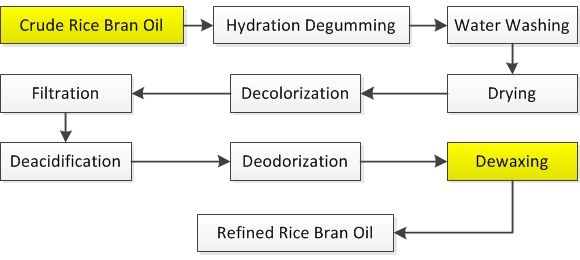

In the rice bran oil refining process, various impurities in crude rice bran oil are removed through four main steps of degumming, deacidification, decolorization and deodorization, so that rice bran oil meets the national standard of finished oil.

In addition, the high wax content in rice bran oil will affect the taste of rice bran oil, so the rice bran oil dewaxing machine is also required in whole rice bran oil production process. Rice bran oil dewaxing equipment can be installed in the same workshop as rice bran oil refining machine. Some manufacturers will design dewaxing in the middle of the four rice bran oil refining process. Huatai Oil Machinery's design is to refine first and then dewax. The rice bran oil obtained after dewaxing can meet the standard of first-class edible oil.

| Item | Index |

| Color (133.4 slots) | Y20 R1.8 |

| Smoke point (℃) | 215 |

| Water and volatile matter | 0.02% |

| Freezing test (0℃ 5.5H) | Clear\Transparent |

| Acid value (mgKOH/g) | 0.15 |

| Peroxide value (mmol/kg) | 4 |

The above is an introduction to rice bran oil extraction production line -a complete set of machine from raw materials to finished oil. If you have a stable source of rice bran raw materials, then investing in a rice bran oil processing plant would be a good choice. Huatai Oil Machinery is looking forward to working with you!

* Please note: We don't recruit any workers and no Job chance.